Project Concept and Scope

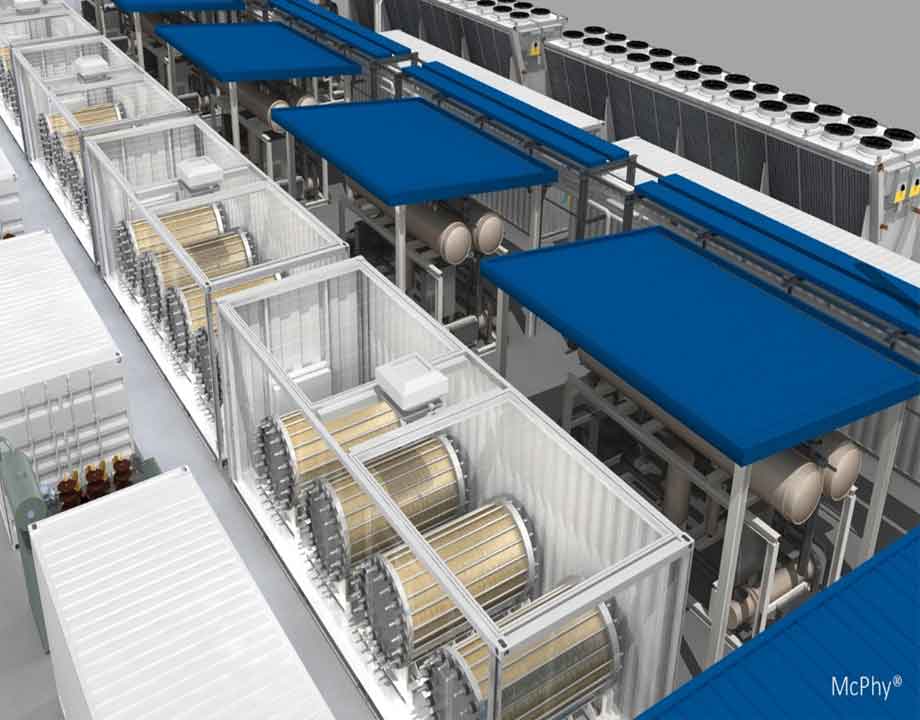

The project focuses on the on-site or near-site production of green hydrogen using renewable energy-powered electrolysis systems. Hydrogen is supplied directly to food-processing facilities and utilized in:

- Oil and fat hydrogenation processes

- Food-grade industrial processing requiring high-purity hydrogen

- Supporting energy systems where clean fuel is required

All project phases are delivered under a full EPC (Engineering, Procurement, and Construction) framework, ensuring seamless integration with existing food-industry infrastructure.

Benefits of the Project

- Ensuring Production Continuity

On-site hydrogen production minimizes exposure to gas supply interruptions and energy shortages. - High-Purity, Food-Grade Hydrogen

Green hydrogen produced via electrolysis meets stringent quality requirements for food processing and hydrogenation applications. - Improved Product Quality and Safety

Clean hydrogen contributes to consistent processing conditions and higher product purity. - Reduced Environmental Impact

Replacing fossil-based hydrogen significantly lowers greenhouse gas emissions and environmental footprint. - Energy Cost Optimization

Renewable-powered hydrogen production stabilizes long-term energy costs and reduces exposure to fuel price volatility. - Compliance with Sustainability and Export Standards

Supports alignment with international environmental regulations and future carbon-related trade mechanisms.

Strategic Importance for the Food Industry

Food production is directly affected by energy disruptions, with consequences such as:

- Raw material spoilage

- Interrupted production lines

- Increased operational and maintenance costs

Green hydrogen provides a secure, scalable, and sustainable solution that enhances energy resilience while enabling the food industry to transition toward low-carbon and future-ready production systems.

Technologies Applied

✔ Engineering and feasibility assessment

✔ System design and equipment selection

✔ Procurement of certified components

✔ Construction, installation, and commissioning

✔ Operation support and technical training